Spotlight on Global Recycling Day 2024

The composite materials market has been steadily growing in recent years, with its high performance and leverage to reduce emissions increasingly valued by several sectors. In many cases, however, there is a need to better manage the end-of-life of composite materials and to structure their recycling processes. Initiatives in this direction are abundant, and progress is as significant as it is promising.

Established in 2018, Global Recycling Day is a relatively recent initiative, but it continues to gain importance as a focal point for the combined efforts of governments, businesses, NGOs, and civil society to promote sustainable development and address the urgent challenges of climate change and pollution.

Recycling is recognised in the UN’s Sustainable Development Goals 2030. Each year the « Seventh Resource » (recyclables) saves over 700 million tonnes in CO2 emissions and this is projected to increase to 1 billion tons by 2030. Needless to say, this is one of the cornerstones of the circular economy.

The young composite materials industry, poised for sustained growth in the coming years, has embraced this challenge in recent years, as seen in sectors like boating, for example. Despite technical difficulties that may need to be overcome, market players in the composites industry are organising themselves and initiating numerous efforts to standardise recycling and scale it up, while also exploring the potential of upcycling and reuse.

To celebrate Global Recycling Day, the JEC teams present a selection of interesting projects and actions that offer new and inspiring perspectives for the future.

Biobased composite bodywork vehicle wins Africa Eco Race 2024

The 15th edition of Africa Eco Race (AER) ended on January 14th in Dakar, and was the inaugural race of APH-01 vehicles, the new-generation hybrid and sustainable side-by-side vehicles (SSV) developed by Apache Automotive (Belgium), subsidiary of GCK Performance (Auvergne, France). Due to strong weight limitations and its environmental-friendly approach, APACHE Automotive was aiming for bio-based composite-based bodyworks, and thus chose to collaborate with VESO Concept (Occitanie, France). Once the design of the bodywork parts validated, APACHE Automotive put a total trust in VESO Concept for the part prototyping and production : reinforcements, polymers and processes have been defined by the VESO Concept team using an eco-conception approach, to finally deliver a first prototype and two bodyworks in one year.

More information: www.veso-concept.com

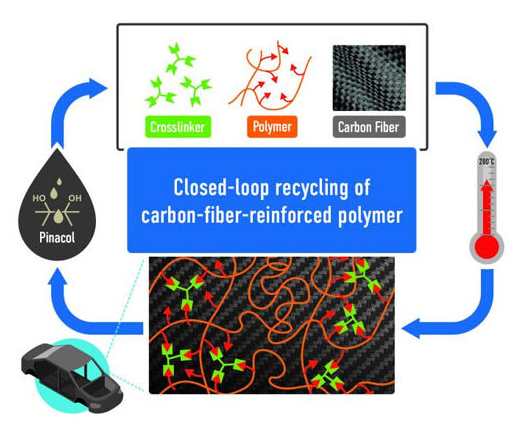

ORNL develops a new process which allows full recovery of starting materials from tough polymer composites

In a win for chemistry, inventors at the Department of Energy’s Oak Ridge National Laboratory have designed a closed-loop path for synthesizing an exceptionally tough carbon-fibre-reinforced polymer, or CFRP, and later recovering all of its starting materials. A lightweight, strong and tough composite material, CFRP is useful for reducing weight and increasing fuel efficiency of automobiles, airplanes and spacecraft. However, conventional CFRPs are difficult to recycle. Most have been single-use materials, so their carbon footprint is significant. By contrast, ORNL’s closed-loop technology, which is published in Cell Reports Physical Science, accelerates addressing that grand challenge.

More information: www.extracthive-industry.com

JEC Composites Magazine Special Issue: Composites Sustainability

JEC Composites Magazine editorial team produces every autumn: the Composites Sustainability Report. Compiling highlights about the part composite materials are playing in creating the sustainable European economy of the future. The purpose of this annual work, rather than results, which quickly become obsolete, is to give examples of approaches contributing to and moving towards sustainability. In the past, JEC Group published special issues about end users industries such as smarter cities, mobility, sports, health, and leisure, all these issues being available to all JEC Composites Magazine subscribers.

More information: www.jeccomposites.com

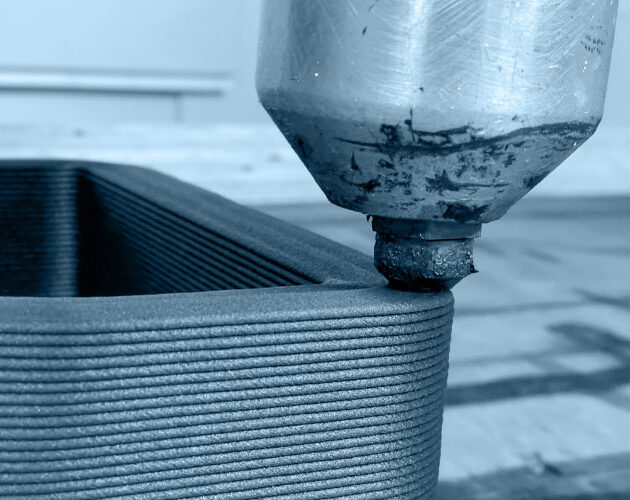

Xenia® Materials unveils XEGREEN® 23-C20-3DP: 100% recycled PET-G carbon fibre reinforced grade for high-performance additive manufacturing

Xenia® Materials, global player in high-performance fibre-reinforced thermoplastic composites production, proudly announces the debut of XEGREEN® 23-C20-3DP at JEC World 2024. This innovative material marks a significant leap in additive manufacturing, bringing forth unmatched performance, sustainability, and versatility. XEGREEN® 23-C20-3DP, a PET-G (polyethylene terephthalate glycol-modified) with 20% carbon fibre reinforcement, represents a meticulous engineering effort to meet the demands of applications requiring superior strength, minimal warpage, and environmental responsibility.

More information: www.xeniamaterials.com

IMT Nord Europe receives €10 million to complete the ECOHYDRO project

IMT Nord Europe announces that it has received a €10 million grant from the European Commission to implement the Economic Manufacturing Process of Recyclable Composite Materials for Durable Hydrogen Storage (ECOHYDRO) project. Funded as part of the HORIZON EUROPE funding program for research and innovation for a four-year period, this international project aims to develop a new recyclable thermoplastic resin with specific functionalities (self-repairability, fire resistance), a new, more cost-effective filament winding process to manufacture hydrogen tanks, digital models to predict the residual life of tanks using Structural Health Monitoring technology via built-in sensors and artificial intelligence algorithms and new composite recycling technology to recover carbon fibers from tanks at the end-of-life and reuse them to manufacture new parts.

More information: www.imt-nord-europe.fr

Acciona Energía highlights the recycling of composites

At the end of 2023, the Spanish group drew attention to composite material recycling in a unique way. They collaborated with the brand El Ganso to develop sneakers made largely from recycled wind turbine blades. Through an innovative process of reducing glass and carbon fibres and epoxy resins, a powder is obtained and combined with rubber to create a shoe sole. The sneakers branded El Ganso feature the graphic symbol of a wind turbine. The shoes are derived from a 23-meter-long wind turbine blade from the Aibar wind farm in the Navarre region of Spain. This blade has been in service since 1998, producing an estimated 12,500 MWh.

More information: www.acciona-energia.com

JEC Composites Innovation Awards 2024: here are the 11 winners

Annually, the JEC Composites Innovation Awards recognize successful initiatives and collaborative efforts within the composites industry. Over the past 26 years, the program has engaged over 2,000 companies globally, honoring 225 companies and 573 partners for their outstanding achievements in composites innovation and effective partnerships. Criteria for the awards include partner involvement in the value chain, project complexity, and commercial potential. The competition is open to any company, university or R&D Center with a compelling collaborative innovation or concept to showcase. The success of participants is closely tied to partnerships and collective intelligence. Beyond being a ceremony, these awards serve as a platform to spotlight potentially undisclosed projects, offering inspiration and motivation to an expert audience eager to explore new frontiers.

More information: www.jeccomposites.com

DOE announces phase one prize winners to boost recycling for a circular wind energy economy

The U.S. Department of Energy announced 20 winners of the first phase of the Wind Turbine Materials Recycling Prize. The $5.1 million, two-phase competition funded by the Bipartisan Infrastructure Law helps develop a cost-effective and sustainable recycling industry for key wind turbine materials not currently recycled commercially. Robust, domestic recycling options for fiber-reinforced composites and rare earth elements will help the environment by lowering the United States’ need to extract and process raw materials. The reuse of more critical materials would also decrease dependence on imports, which would make domestic supply chains less susceptible to price volatility and disruptions. By creating a circular economy for wind energy systems, the Wind Turbine Materials Recycling Prize supports the Biden-Harris Administration’s goals of achieving a carbon-pollution-free power sector by 2035 and net-zero emissions by 2050.

More information: www.energy.gov

Thermolysis launches fully recyclable products using recycled carbon fibre at JEC World 2024

Introduced the RCF brand, a sustainable initiative committed to complete recycling, in pursuit of the goal of zero waste. To dispel the misconception that composite materials cannot be recycled, Thermolysis is dedicated to developing a range of products that can be entirely recycled, utilizing recycled materials as a foundation. They are pleased to announce the establishment of a socially responsible green brand, “RCF”. This brand designs and produces a range of bicycle accessories and daily necessities, using carbon fiber recycled by Thermolysis. The product lineup of the RCF brand comprises bicycle accessories, including bottle cages, pads, seats, cycling shoe boards, light stands, and fenders. All these products are crafted from Thermolysis’ recycled carbon fiber, ensuring not only their lightweight characteristics but also retaining excellent mechanical strength.

More information: www.thermolysis-asia.com

BÜFA Composite Systems introduces sustainable product portfolio and new environmental label BÜFA®-future

BÜFA Composite Systems, Europe’s leading distributor and manufacturer of polyester resin specialties, announces the launch of its comprehensive sustainable product range and the innovative sustainability label BÜFA®-future. The company, recognised for its innovation and commitment to sustainability, is setting a new standard in the composites industry. With more than a century of experience in the chemical industry, BÜFA has become synonymous with innovation, quality and sustainability. The introduction of the sustainable product range is a further step in the company’s journey to make a positive impact on the environment while meeting the needs of the market.

More information: www.buefa-composites.com

Toray Carbon Fibers Europe to supply bio-circular Torayca carbon fibre for HEAD’s prototype racquets

Toray Carbon Fibers Europe S.A. announced that HEAD Sports GmbH (HEAD) is developing prototype tennis racquets and pickleball paddles made with Toray’s bio-circular carbon fibre using the mass balance approach as certified by the ISCC PLUS standard. Toray Carbon Fibers Europe and HEAD are leaders in producing premium high-performance products and are committed to reducing the carbon footprint of their activities. The decision to build a partnership to develop new racquets was also based on Toray’s ability to provide bio-circular carbon fibre (mass balance approach) for this project. Toray Carbon Fibers Europe recently obtained ISCC PLUS certification in September 2023 and is able to supply bio-circular carbon fibre using the mass balance approach. Therefore, products manufactured with bio-circular carbon fibre will emit less CO2.

More information: www.toray-cfe.com

A life on the ocean waves with flax technical innovations

The adoption of composite parts based on flax fibres by the Marine Industry continues to grow, with major OEMs as well as smaller shipyards now aiming to take advantage of the reduced carbon impact and impressive mechanical properties they can provide. As a member of the Alliance for European Flax-Linen and Hemp, Bcomp, headquartered in Fribourg, Switzerland, has this year been working with Northern Light Composites (nlcomp), based in Monfalcone, northern Italy, on the creation of what is billed as the first fully recyclable nine-metre-long sailing boat – the ecoRacer30.

The boat is based on nlcomp’s proprietary rComposite technology – a combination of thermoplastic resins and BComp’s ampliTex high-performance natural fibre reinforcement fabrics and patented powerRibs technology.

More information: www.allianceflaxlinenhemp.eu